At present, the preparation methods of spherical tungsten powder include: (1) plasma method; (2) tungstate hydrogen reduction method; (3) tungsten halide hydrogen reduction method; (4) cyclic oxidation method. Although they can prepare spherical W powder, they have the disadvantages of complex process, long production cycle, low production capacity, high manufacturing cost, low sphericity, and uneven product particle size distribution. Therefore, the following will introduce a new production method of spherical tungsten powder. The specific steps are as follows:

(1) Weigh a certain amount of ammonium paratungstate (APT), put the ammonium paratungstate into the tubular resistance furnace in a closed loop, and heat it at 700~800℃ and keep it for 30-60min.

(2) Then take the sample out of the tubular resistance furnace, put the taken out powder into the spheroidizing equipment (HYB), and spheroidize the particles under the conditions of a rotation speed of 3000-4500r/min and a processing time of 10-60min treatment to remove the edges and corners of the particles.

(3) Sieving the particles after the spherical treatment, and then put them into a tubular resistance furnace to reduce, set the hydrogen gas reduction temperature to 650~700℃, and the reduction time to 60~90min to get the product.

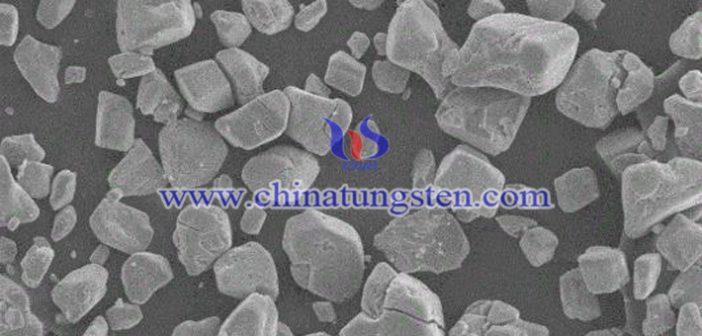

The advantages of this spherical tungsten powder production method are: spheroidizing the calcined ammonium paratungstate by mechanical method, compared with no treatment, before it is in the shape of polygonal particles, sharp edges and corners, amorphous, rough surface; through ball milling treatment hydrogen reduction, it has a nearly spherical shape and a relatively uniform particle distribution. At the same time, this method is lower in production cost, cheaper in price, shorter in process flow, pollution-free, environmentally friendly, convenient, and the treatment method and process flow are lower than the prior art in which conventional tungsten powder is further processed to obtain spherical tungsten powder. The parameters are easy to control.