In addition to tungsten-copper and tungsten-silver alloys, two-phase tungsten-based alloys also include tungsten molybdenum (W-Mo) alloy. Depending on the design shape, W-Mo alloys can be classified into rectangular prisms, cubes, hexagons, cylinders, and spheres. Under identical raw material ratios, production processes, and parameters, they exhibit completely the same physical and chemical properties, but differ in applications.

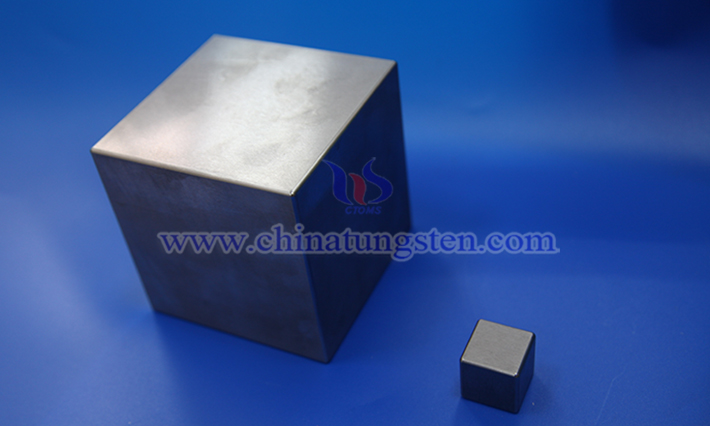

Taking tungsten molybdenum alloy cubes as an example, they are alloy materials composed of refractory metals tungsten and molybdenum, with the English name tungsten molybdenum alloy cube. The tungsten content in commonly used tungsten molybdenum alloys is 30%–50%. Note: When the molybdenum content exceeds the tungsten content, the tungsten molybdenum alloy can also be called molybdenum-tungsten alloy.

In terms of physical and chemical properties, W-Mo alloy cubes feature high melting point (2620–3410℃), high density, high strength, high hardness, low thermal expansion coefficient, low vapor pressure, good electrical and thermal conductivity, and wear resistance. Note: The alloy's performance varies with different raw material ratios, primarily reflected in the melting point, hardness, and strength generally increasing with higher tungsten content.

In terms of production process, W-Mo alloy cubes can be produced using powder metallurgy, vacuum arc melting, vacuum electron beam melting, or 3D printing technology. For powder metallurgy: first mix tungsten powder and molybdenum powder, then press into green compacts using a mechanical press, and finally sinter in a high-temperature furnace to obtain the desired product. For 3D printing: first mix tungsten and molybdenum powders, then prepare spherical precursor powder using spray granulation technology, and finally perform sintering and spheroidization treatment.

In terms of applications, tungsten molybdenum alloy cubes can serve not only as paperweights and counterweights for various mechanical equipment but also as souvenirs.