Tungsten alloy collimators play a core role in the field of radiation control, and their diversified structural designs affect the geometric precision and application efficiency of the radiation beam.

According to different structural designs, the classification of tungsten alloy collimators includes flat-plate type, multi-leaf type, annular type and conical/pinhole type, which have certain differences in construction principles, functional positioning and actual deployment scenarios.

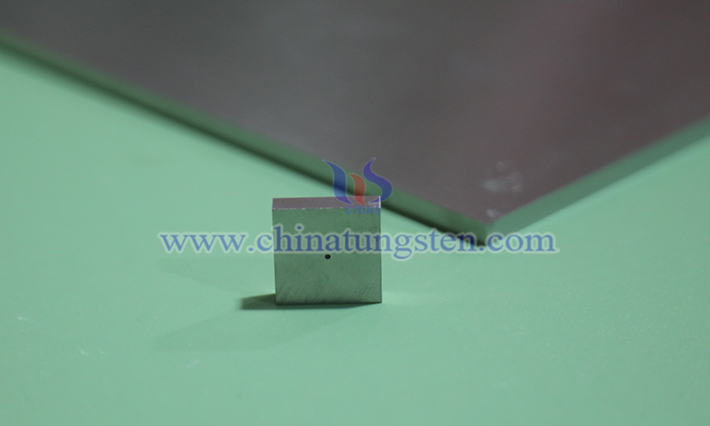

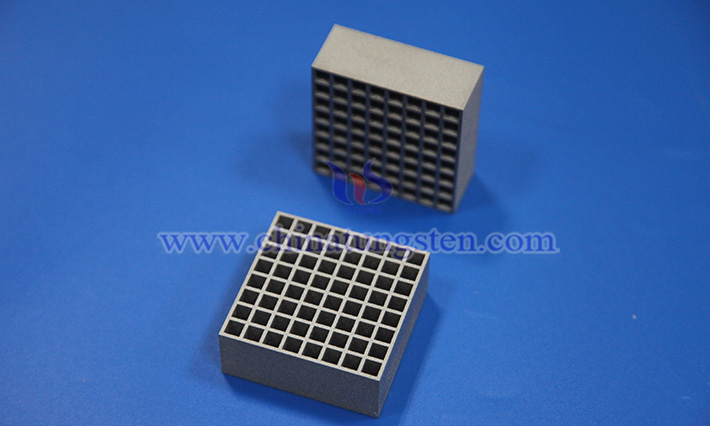

Flat-plate collimators use single-layer or multi-layer tungsten alloy plates as the substrate, forming regularly arranged matrix through-hole arrays on the plate surface through precision mechanical processing or electrical discharge machining.

This structure essentially constitutes a set of parallel micro-channels, allowing only rays consistent with the plate normal direction to pass, while scattered photons or particles incident from other directions are absorbed and blocked by high-density tungsten alloy.

This type of collimator is widely adopted in basic X/γ-ray imaging systems, industrial non-destructive testing equipment and scientific particle beam screening experiments due to mature manufacturing processes and controllable costs.

Multi-leaf collimators are composed of dozens to hundreds of independently servo-driven thin tungsten alloy leaves.

The thickness of each leaf is usually controlled at the millimeter level.

The leaf arrays can reconstruct the radiation field shape in real time under computer control, achieving geometric conformity with the target contour.

In medical linear accelerator intensity-modulated radiotherapy, multi-leaf collimators confine the high-dose area to the tumor volume through layer-by-layer or continuous arc scanning, while minimizing the dose to surrounding normal tissues.

Annular collimators use a ring-shaped tungsten alloy as the main body, with multiple sets of radially or axially arranged collimation channels embedded, forming circumferential multi-view radiation entrances.

This design is suitable for scenarios requiring 360° surround detection, such as industrial computed tomography scanning, multi-angle γ-ray flaw detection and beam shaping in high-energy physics experiments.

In industrial CT systems, annular collimators are arranged around the workpiece, allowing rays to penetrate the inspected object from different directions, combined with rotational acquisition to achieve three-dimensional reconstruction; in high-energy physics beam lines, they constrain particle trajectories through channel geometry, suppress background noise, and ensure that downstream detectors only record primary beam events.

Conical or pinhole collimators adopt a conical cavity structure, with single-hole or multi-hole pinhole arrays opened at the top of the cavity, constituting a typical pinhole imaging optical system.

In SPECT nuclear medicine imaging and γ camera equipment, this collimator uses the principles of pinhole diffraction and geometric projection to project γ photons emitted by radioactive tracers onto scintillator crystal arrays, forming high-resolution functional images.

Compared with parallel-hole collimators, the pinhole structure significantly improves spatial resolution while maintaining sensitivity, and is suitable for small animal imaging or superficial organ imaging.