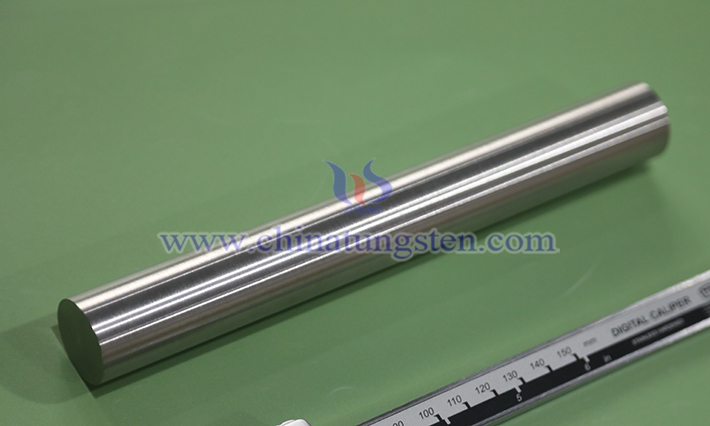

The application classification of tungsten alloy rods is a direct reflection of the matching between their properties and scenario requirements. Different fields have differentiated requirements for core properties of materials such as melting point, strength, density, electrical and thermal conductivity, and corrosion resistance, which in turn promote targeted composition design and processing technology optimization. Based on different application scenarios, the classification of tungsten alloy rods includes alloy rods for the welding field, alloy rods for the electronic field, alloy rods for the military field, etc.

Tungsten alloy rods for welding field: Their requirements are a comprehensive embodiment of arc stability, ablation resistance and electrical conductivity. They need to maintain structural stability in a high-temperature arc environment, transmit energy and reduce their own loss. Rare earth-doped tungsten alloy rods refine grains and improve electron emission efficiency by adding rare earth elements such as cerium, lanthanum and yttrium. When used in plasma welding of aerospace components, they can maintain stable electrode shape under high current.

Tungsten alloy rods for electronic field: Their requirements are a combination of high-temperature stability, low evaporation rate and precise dimensions. They need to maintain structural integrity in a high-temperature working environment while meeting the assembly requirements of miniaturization and high precision. Tungsten alloy rods for electrodes are mainly tungsten-copper alloys, which have both high melting point and high electrical conductivity. Used as electrodes for high-power semiconductor devices and conductive rods for vacuum switches, they can quickly dissipate heat from chips. Tungsten-silver alloy rods for heat dissipation are used in heat dissipation substrates of 5G base station power amplifiers to solve the heat dissipation problem of high-density packaging.

Tungsten alloy rods for military field: Their requirements include high melting point, high strength and high hardness. Tungsten alloy rods for armor-piercing projectiles are mainly tungsten-nickel-iron alloys, which have high density, high tensile strength and good impact toughness. Used as the core of armor-piercing projectiles for main battle tanks, they can achieve deep penetration of homogeneous armor.

Tungsten alloy rods for counterweight field: Their requirements are a combination of high density, good machinability and cost adaptability. They need to achieve large weight in a small volume and be easy to process into complex shapes; they are used in scenarios such as racing counterweights and clock balance wheels; they are also used as balance bars for machine tool spindles and gyro rotors for inertial navigation systems.