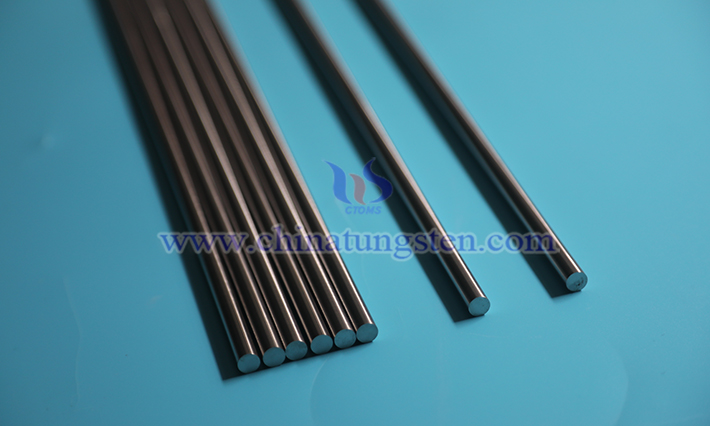

Tungsten-molybdenum alloy rods belong to the body-centered cubic solid solution system, achieving comprehensive optimization of microstructure and macroscopic properties through the infinite mutual solubility of tungsten and molybdenum. From the perspective of material composition and microstructure, the tungsten-molybdenum ratio in tungsten-molybdenum alloy rods can be flexibly adjusted according to application needs, usually with tungsten content dominating the overall framework, while molybdenum content is uniformly distributed in the tungsten lattice as a solid solution strengthening phase. This solid solution structure ensures the phase stability of the alloy rods over a wide temperature range, avoiding the risk of second-phase precipitation or brittle intermediate phase formation. The atomic radius of molybdenum is similar to that of tungsten; its solid solution into the tungsten lattice produces a lattice distortion effect, effectively pinning dislocation movement, thereby maintaining high strength levels at high temperatures. At the same time, the addition of molybdenum significantly lowers the ductile-brittle transition temperature of tungsten, enabling the alloy rods to maintain good deformation coordination from room temperature to high-temperature ranges.

In terms of performance characteristics, the outstanding advantages of tungsten-molybdenum alloy rods stem from the synergistic thermodynamic and mechanical responses of tungsten and molybdenum. Tungsten's high melting point and low vapor pressure endow the alloy rods with excellent heat resistance; the solid solution strengthening effect of molybdenum greatly enhances the high-temperature strength and creep resistance of the alloy, enabling superior dimensional stability and load-bearing capacity under long-term thermal loads. Compared to pure tungsten rods, the recrystallization temperature of tungsten-molybdenum alloy is significantly increased, with suppressed grain coarsening tendency, ensuring mechanical reliability after high-temperature service. In addition, tungsten-molybdenum alloy rods have good thermal shock resistance and initial oxidation resistance, maintaining surface cleanliness over long periods in vacuum or inert atmospheres, with moderate thermal conductivity that changes gently with temperature, facilitating uniform heat distribution.

In high-temperature structural applications, tungsten-molybdenum alloy rods mainly serve load-bearing and heat transfer components in hot environments. In sapphire single crystal growth furnaces, tungsten-molybdenum alloy rods are often made into heating element support rods or crucible suspension rods. In electron beam welding equipment or X-ray tubes, tungsten-molybdenum alloy rods are processed into cathode support rods or electron gun components, utilizing molybdenum to reduce tungsten's brittleness and improve emission stability, ensuring focusing accuracy and long-term consistency of the electron beam. In space nuclear reactors, tungsten-molybdenum alloy rods made into control rod drive shafts can operate long-term under coupled radiation and high-temperature environments, ensuring reactor power regulation.