In modern chemical processes, pumps are key equipment for transporting various media, and the performance of their mechanical seals directly determines the reliability and safety of the equipment's operation. As the core material of mechanical seal rings (dynamic and static rings), Tungsten Carbide Balls, with their superior comprehensive performance, have become one of the preferred materials for handling harsh chemical conditions, and are hailed as the "reliable guardians" of chemical pump seals.

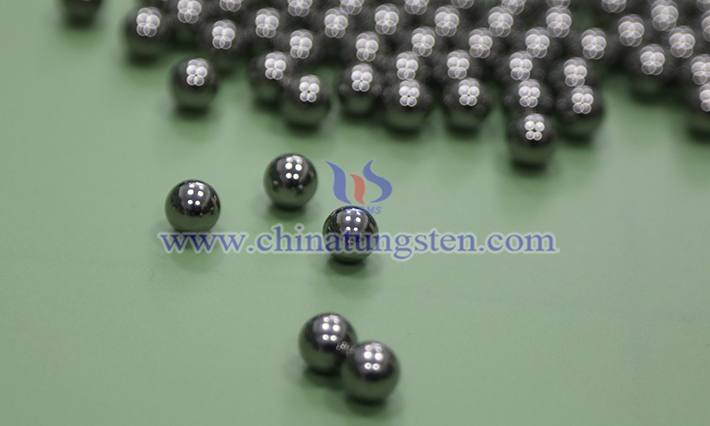

Hard alloy is a composite material made by sintering micron-sized powder of high-hardness, high-wear-resistant refractory metal carbides (mainly tungsten carbide WC) with a metallic binder phase (such as cobalt Co) through powder metallurgy. This unique structure endows tungsten carbide balls with unparalleled characteristics:

First, excellent wear resistance. Tungsten carbide itself has extremely high hardness (reaching HRA90 or higher), enabling the tungsten carbide balls to effectively resist frictional wear when rotating at high speeds and contacting the mating parts. This significantly extends the service life of the sealing ring and reduces leakage and frequent downtime for maintenance caused by wear.

Secondly, it exhibits excellent corrosion resistance. By adjusting the binder phase composition (such as using a nickel-based binder phase with better corrosion resistance), tungsten carbide balls can withstand the erosion of many corrosive media commonly used in chemical production, such as acids, alkalis, salts, and organic solvents, maintaining the stability and integrity of the material and preventing failure due to corrosion.

Furthermore, it possesses high strength and toughness. Compared to pure ceramic materials, cemented carbide, while possessing high hardness, has a metallic binder phase that gives it higher bending strength and a certain degree of toughness. It can withstand the mechanical and thermal stresses generated during start-up and shutdown, pressure fluctuations, or minor particulate impacts, effectively preventing brittle fracture.

In addition, it also has a low coefficient of friction and good self-lubricating properties, which helps reduce frictional heat at the sealing end face, reduce power consumption, and improve operating efficiency.

In summary, tungsten carbide balls for chemical pump seals, with their combined advantages of high hardness, high wear resistance, strong corrosion resistance, and excellent mechanical strength, perfectly solve the sealing problems faced by chemical pumps when conveying harsh media such as highly corrosive, particulate-containing, high-temperature, and high-pressure media. Their widespread application greatly improves the continuity, safety, and economy of chemical production, making them an indispensable key component for ensuring the stable, long-term, and efficient operation of modern process industries.