High-pressure valves are core equipment in the petroleum, chemical, and natural gas industries, often operating under extreme conditions. The medium pressure can reach tens of megapascals, and the temperature range is -196℃ to 600℃, accompanied by corrosion, erosion, and wear. Traditional steel or stainless-steel balls are prone to failure under these conditions: rapid surface wear leads to leakage, ball deformation causes jamming, and even sudden bursting can lead to accidents. Cemented carbide balls (mainly composed of WC-Co or WC-Ni) have become the preferred choice for high-pressure valve sealing pairs due to their ultra-high hardness (HRA 88-93), excellent wear resistance, and corrosion resistance.

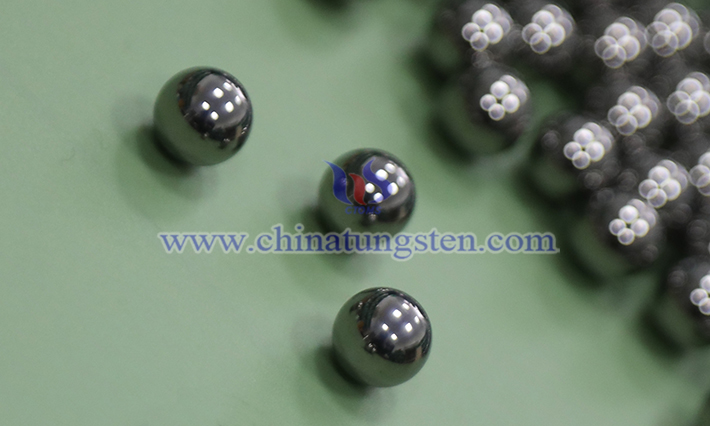

1. Material Properties of Cemented Carbide Balls for High-Pressure Valves

The hardness of cemented carbide balls is 3-5 times that of quenched steel, and their compressive strength exceeds 4000 MPa, far exceeding the approximately 500 MPa of 316L stainless steel. The cobalt-bonded phase imparts good toughness and prevents brittleness; the nickel-based structure enhances resistance to acid and alkali corrosion, making it suitable for H?S and CO? environments. Its low coefficient of thermal expansion (approximately 5 × 10??/℃) results in low thermal stress when matched with the valve seat, ensuring stable high-temperature sealing.

2. Manufacturing Process of Cemented Carbide Balls for High-Pressure Valves

The raw materials are high-purity WC powder (particle size 0.2-0.8 μm) and Co/Ni powder, ball-milled and mixed at a ratio of 6%-12%, spray-dried and granulated, then cold isostatically pressed (300 MPa), followed by vacuum sintering at 1500℃ or hot isostatic pressing at 1450℃. The sintered body is diamond-ground to control sphericity within 0.5 μm and surface roughness Ra 0.02-0.05 μm. The diameter tolerance is ±0.001 mm, meeting the API 598 zero-leakage standard.

3. Performance Advantages of Cemented Carbide Balls for High-Pressure Valves

Abrasion and Erosion Resistance: In sand-containing natural gas, the wear rate of cemented carbide balls is only 1/50 that of steel balls, extending service life by 5-10 times.

High-Temperature and High-Pressure Sealing: At 600℃ and 70 MPa, the contact stress is uniform, and the leakage rate is <10?? cm3/s. Corrosion Resistance: The annual corrosion depth of WC-Ni balls in media with pH 1-14 is <0.01 mm. Fatigue Resistance: After 10? cycles of switching, there is no pitting or peeling on the ball surface.