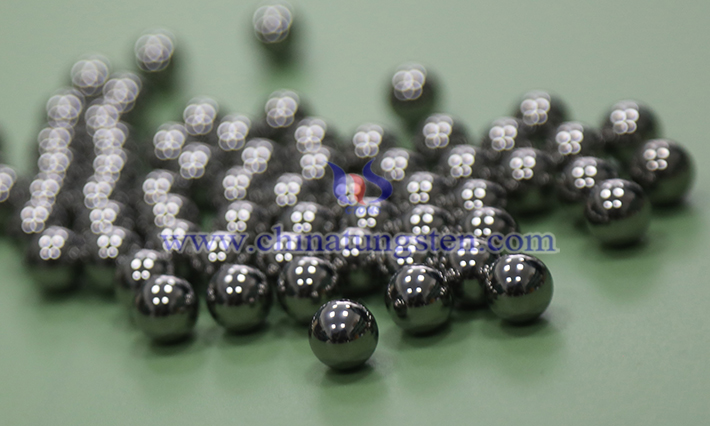

These cemented carbide balls are high-performance components specifically designed for extreme marine environments. Their core characteristics are highly compatible with the needs of deep-sea engineering, making them key components for deep-sea exploration, resource extraction, and pipeline systems.

1. Material Composition and Performance Advantages of Cemented Carbide Balls

Cemented carbide balls use tungsten-cobalt (YG series) or tungsten-nickel (YN series) cemented carbide as the base material, manufactured through a vacuum sintering process. The tungsten carbide (WC) content is over 92%, with cobalt (Co) or nickel (Ni) as the binder. Their hardness is ≥90.5 HRA, and their density is approximately 14.9 g/cm3, twice that of steel balls. Their wear resistance is tens to hundreds of times that of traditional steel balls. The high-density structure reduces porosity, giving the material excellent resistance to corrosive media such as acids and alkalis, and significantly improving its bending strength, allowing it to withstand high pressure differentials and impact loads. For example, in complex conditions such as sand-bearing wells and heavy oil wells, after the cemented carbide valve ball and seat are fitted together, the pressure value remains unchanged within 10 seconds when the vacuum is reduced to below 0.36 kgN/cm2, verifying its sealing reliability.

2. Application Scenarios of Cemented Carbide Balls in Deep-Sea Engineering

Deep-Sea Drilling and Pump Valve Systems: As a pump valve ball, cemented carbide balls must withstand high pressure, high temperature, and highly corrosive media in formations hundreds to thousands of meters deep. Its bidirectional sealing design, rapid opening and closing capability of 0.05-0.1 seconds, and flow regulation function of the V-shaped opening structure can efficiently control oil and gas transportation. For example, in deep-sea drilling, the nominal pressure range of cemented carbide valve balls covers vacuum to 42 MPa, adapting to cryogenic to high-temperature environments.

Pressure hulls and counterweight systems: Their high density makes them ideal counterweight materials for deep-sea pressure hulls. Taking a 2-meter diameter spherical pressure hull as an example, cemented carbide spheres can evenly distribute weight, improving structural stability. Simultaneously, their low coefficient of thermal expansion ensures dimensional accuracy, making them suitable for full-bore welded pipe installation.

Precision instruments and mechanical transmissions: In inertial navigation systems, ball screws, and other applications, the weight uniformity and high rotational accuracy of cemented carbide spheres reduce energy loss and extend equipment life. For example, in the precision bearings of deep-sea probes, their wear resistance supports continuous operation, with a lifespan 3-5 times that of steel balls.