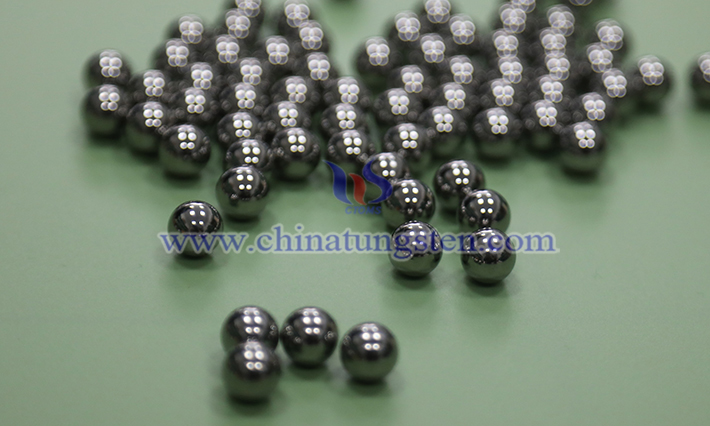

A cemented carbide ball for precision measurement is a key basic component made primarily of micron-sized powder of high-hardness refractory metal carbides (such as tungsten carbide WC and titanium carbide TiC), with cobalt (Co), nickel (Ni), or molybdenum (Mo) as a binder. It is sintered in a vacuum furnace or hydrogen reduction furnace using powder metallurgy processes and has important applications in precision measurement and instrument calibration.

1. Main characteristics of cemented carbide balls

Extremely high hardness and wear resistance: Its hardness is typically above HRA 91, approaching that of diamond. This allows it to withstand long-term, high-intensity friction and wear, with a service life dozens of times longer than ordinary steel balls, effectively ensuring the long-term stability of measuring tools.

Excellent dimensional stability: Cemented carbide balls possess an extremely low coefficient of thermal expansion and excellent corrosion resistance, enabling them to withstand the erosion of chemicals such as acids and alkalis. This means that they maintain shape and dimensional stability even under temperature fluctuations or harsh environments.

Superior compressive strength: Their compressive strength can reach over 6000 MPa, allowing them to withstand high-load environments without deformation.

Extremely high precision: Through precision grinding and polishing, cemented carbide balls can achieve high precision grades of G5-G10, with extremely small diameter tolerances and high surface finish. Their roundness error can be controlled at the nanometer level, meeting the highest measurement standards.

2. Brief Description of Cemented Carbide Ball Manufacturing Process

The manufacturing of cemented carbide balls is a precision process, mainly including raw material preparation (mixing tungsten carbide powder and cobalt powder in proportion), pressing and molding, high-temperature sintering, and final precision grinding and polishing. Rigorous quality inspection, including the use of optical measuring instruments and roundness testers to verify dimensions, roundness, and surface quality, is a crucial step in ensuring the accuracy of the final product.

3. Main Uses of Cemented Carbide Balls in Precision Measurement

As measuring probes: In contact probes of equipment such as coordinate measuring machines (CMMs) and roundness testers, cemented carbide balls are used as probe tips. Their high hardness and wear resistance minimize wear on the surface of the workpiece being measured, thus ensuring the long-term accuracy and consistency of measurement data.

As calibration benchmarks: Thanks to their extremely high dimensional stability and known precise geometry, cemented carbide balls are often used as standard gauges for calibrating precision instruments such as CMMs, roundness testers, and profilometers. For example, when calibrating a CMM, a standard ball with known precise dimensions and roundness is fixed on the worktable, and the spatial coordinate accuracy of the measuring machine is corrected and verified by measuring this ball.

For specialized inspection tools: They can also be found in certain specific high-precision inspection scenarios. For example, gasket groove ball gauges used for inspecting sealing grooves in the oil and aerospace industries employ high-precision cemented carbide balls as measuring contacts to achieve micron-level accuracy.

Applications in surface measurement and optical calibration: Due to their ability to be machined to extremely smooth surfaces, cemented carbide balls also serve as reference standards for surface roughness measurement. Furthermore, in optical measurement equipment (such as laser interferometers), their stable geometry and high reflectivity make them suitable as calibration targets or positioning elements.