Cemented carbide bearing balls for automotive use are miniature masterpieces that integrate cutting-edge materials science and precision manufacturing processes in modern industry. Though small, they act like "black diamonds" in a vehicle's transmission system, silently bearing loads and rotating stably, a core element ensuring the efficient, smooth, and durable operation of a car.

Compared to traditional steel ball bearings, cemented carbide ball bearings offer revolutionary advantages. Their material is primarily composed of hard tungsten carbide particles and tough cobalt, combined using powder metallurgy technology, giving them unparalleled properties.

First, they possess extreme hardness and wear resistance. Under high-speed rotation and continuous pressure, ordinary materials inevitably fail due to fatigue and wear, while cemented carbide bearing balls virtually ignore this wear, extending their service life several times over, especially under harsh conditions or with insufficient lubrication.

Second, they exhibit excellent compressive strength and dimensional stability. Even under immense loads, it tenaciously resists deformation, maintaining its perfect spherical shape. This inherent rigidity ensures the bearing's dynamic precision at high speeds, effectively reducing vibration and noise, and providing a quieter, smoother experience in the cockpit.

Furthermore, it boasts exceptional corrosion resistance. It can readily withstand the onslaught of moisture, salt, or chemically corrosive media, a characteristic crucial for ensuring the long-term reliability of critical components in electric vehicles or vehicles exposed to complex environments.

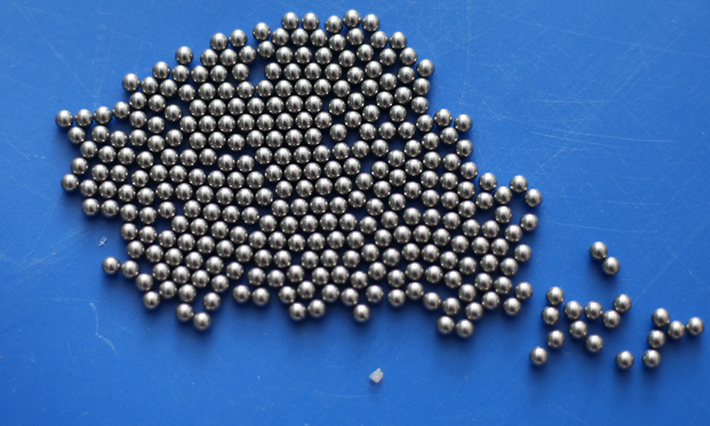

Manufacturing these tiny precision components is an art in itself. From mixing, pressing, and sintering to the final multi-stage precision grinding and polishing, every step demands near-obsessive precision control. The final product achieves a mirror-like surface finish, with its roundness and dimensional tolerances controlled at the micrometer level to ensure that each ball rolls smoothly with near-zero friction.

In today's automotive industry, moving towards electrification and intelligence, the value of cemented carbide bearing balls is becoming increasingly apparent. They play an indispensable and crucial role in high-efficiency electric drive systems, turbochargers, transmissions, and various pump and valve systems. They not only directly improve the efficiency and lifespan of components, but also indirectly contribute to improving fuel economy or extending the driving range of electric vehicles by reducing energy loss.