High-precision equipment places extremely stringent performance requirements on bearing balls, and tungsten carbide bearing balls, thanks to their unique material properties and precision manufacturing processes, have become core components in the high-end equipment field.

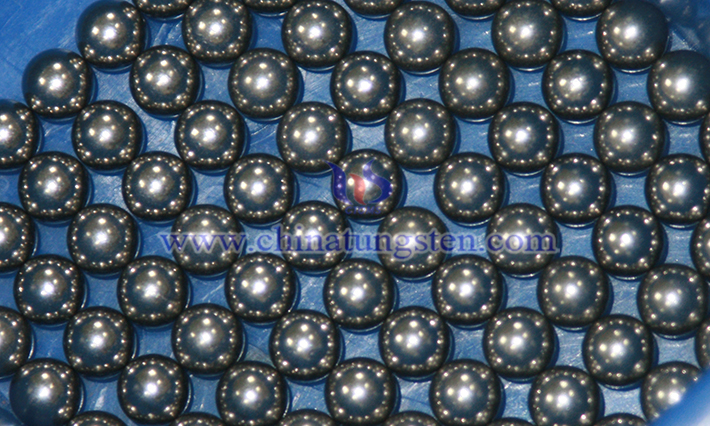

Tungsten carbide bearing balls use high-hardness metal carbides such as tungsten carbide (WC) as the matrix, and are sintered in a vacuum environment using binders such as cobalt (Co) or nickel (Ni). Their hardness approaches that of diamond, their wear resistance is several times higher than that of traditional steel balls, and they possess excellent corrosion resistance and high-temperature resistance, enabling them to maintain long-term stable operation under extreme conditions.

In the field of precision manufacturing, the application of tungsten carbide bearing balls significantly improves equipment performance. For example, in the aerospace field, its zero-magnetic properties prevent electrolytic corrosion caused by electromagnetic interference during high-speed flight, ensuring the reliability of spindle bearings. In medical devices, bearing balls made of zirconia ceramics and cemented carbide, with their biocompatibility and ultra-smooth surface, reduce the wear rate of artificial joints to one-tenth that of traditional metal bearings, extending their service life to over twenty years. Furthermore, in high-end machine tools, wind turbine gearboxes, and other applications, cemented carbide balls significantly extend equipment maintenance cycles by reducing frictional loss and thermal deformation, driving industrial production towards high efficiency and low carbon emissions.

Innovations in manufacturing processes further enhance the precision advantages of cemented carbide balls. Through precision grinding and polishing technologies, the roundness and surface finish of the balls can reach sub-micron levels, effectively reduce vibration and noise and meet the micron-level precision requirements of optical instruments and semiconductor equipment. Simultaneously, modular design supports customization of non-standard specifications according to drawings, and combined with laser marking and rust-proof packaging, ensures quality control throughout the entire process from production to transportation.