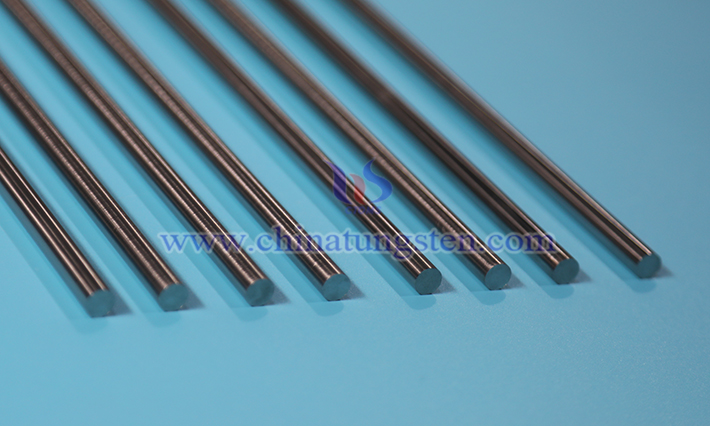

Tungsten-containing high-entropy alloy rod is a rod-shaped material made from a high-entropy alloy with tungsten as one of the main constituent elements through plastic deformation or powder metallurgy processes. It is an alloy material composed of five or more elements in equal or near-equal atomic ratios, with its design core lying in utilizing high configurational entropy to stabilize single-phase or few-phase solid solution structures and avoid brittle intermetallic compound phases common in traditional alloys. Tungsten-containing high-entropy alloys mainly belong to the category of refractory high-entropy alloys, primarily composed of high-melting-point elements such as tungsten, molybdenum, niobium, tantalum, hafnium, zirconium, vanadium, chromium, and titanium, with tungsten, as a metal element with a higher melting point, playing a key role in the alloy.

Tungsten-containing high-entropy alloy rods can be prepared by melting and casting combined with hot working methods. The steps are as follows: high-purity raw materials are repeatedly arc-melted or induction-melted under vacuum or inert gas protection to achieve compositional homogenization, followed by large-deformation plastic processing such as hot isostatic pressing, hot forging, hot extrusion, or hot rotary forging to form rods. This production method can yield dense, segregation-free rod blanks and is suitable for preparing rods with larger diameters.

Tungsten-containing high-entropy alloy rods exhibit significant advantages in high-temperature mechanical properties, softening resistance, and wear resistance. Due to the low diffusion coefficients of elements such as tungsten, molybdenum, and tantalum, the alloy can still maintain structural stability at high temperatures with extremely slow strength degradation. At the same time, the solid-solution strengthening effect brought by lattice distortion endows the material with high hardness at both room temperature and elevated temperatures. Compared with traditional tungsten-nickel-iron and tungsten-nickel-copper high-density alloys, tungsten-containing high-entropy alloys have clear advantages in high-temperature strength, anti-softening ability, and structural stability.

Tungsten-containing high-entropy alloy rods are primarily targeted at high-temperature structural and functional components in extreme service environments. In the nuclear energy field, they can serve as important candidate materials for plasma-facing materials in fusion reactors (such as first walls and divertors); in the defense field, they are regarded as potential replacement materials for next-generation kinetic energy armor-piercing projectile cores and self-sharpening fragments to further improve penetration and self-sharpening performance.