CTIA GROUP LTD tungsten alloy rings are composite annular components with tungsten as the matrix formed by adding nickel, iron, copper or other elements. They represent one of the typical geometric forms of high-density tungsten alloys. As an axisymmetric closed structure, the ring can fully utilize the advantages of tungsten alloys such as high density, high strength and radiation resistance while meeting special requirements for rotational symmetry, uniform counterweight or omnidirectional shielding under specific operating conditions. For any tungsten alloy ring products, please contact CTIA GROUP LTD: sales@chinatungsten.com, 0592-5129595.

1. Performance of Tungsten Alloy Rings

Tungsten alloy rings feature a high density of 16.5–18.8 g/cm3 as their core characteristic, combined with excellent mechanical properties (high strength and toughness), extreme environmental tolerance (high temperature, radiation and corrosion resistance), strong gamma-ray/neutron shielding capability, good machinability, and non-toxic environmental friendliness. They have become core components in aerospace inertial devices, nuclear medicine collimation and shielding, high-temperature load-bearing structures and precision vibration damping applications.

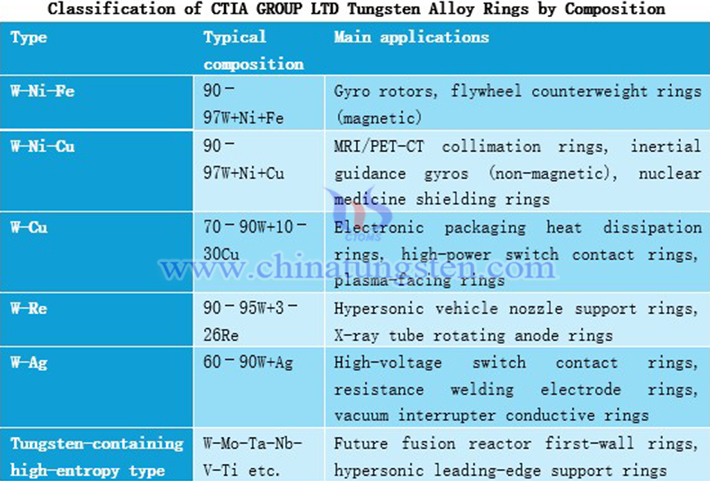

2. Classification of Tungsten Alloy Rings

Depending on material composition, CTIA GROUP LTD tungsten alloy rings are divided into tungsten-nickel-iron alloy rings, tungsten-nickel-copper alloy rings, tungsten-copper alloy rings, tungsten-silver alloy rings, etc., each with distinct applications. Tungsten-nickel-iron alloy rings are mainly used in general counterweight and inertial fields; tungsten-nickel-copper alloy rings are primarily applied in non-magnetic medical and nuclear medicine collimation scenarios; tungsten-copper and tungsten-silver alloy rings are mainly used where electrical/thermal conductivity and arc resistance are required.

3. Performance Comparison of Tungsten Alloy Rings vs. Other Rings

Tungsten alloy rings, with density far exceeding that of lead, titanium and steel, combined with high strength, radiation resistance, high-temperature tolerance and environmental friendliness, hold significant advantages in applications requiring small volume with large mass, strong shielding or reliability in extreme environments. Lead rings, while dense, are toxic and easily deformed; titanium alloy and steel rings cannot meet high-inertia counterweight or efficient shielding tasks due to insufficient density.

4. Applications of Tungsten Alloy Rings

CTIA GROUP LTD tungsten alloy rings, in axisymmetric single-ring or multi-layer nested forms, are widely used in aerospace, nuclear medicine, industrial inspection, nuclear engineering and precision instrumentation fields. Typical applications include high-speed inertial rotors, radiation collimation and shielding, control rod absorption and vibration-damping counterweights. They rely on the material’s high density, excellent mechanical and radiation performance, and geometric controllability to achieve large mass, high inertia, omnidirectional shielding in small volumes and long-term reliable service under extreme conditions.