China Tungsten Industry Development Report (2020)Ⅱ In 2020, in the face of the severe and complex international situation and the arduous tasks…

China Tungsten Industry Development Report (2020)Ⅱ In 2020, in the face of the severe and complex international situation and the arduous tasks…

China Tungsten Industry Development Report (2020)Ⅰ In 2020, in the face of the severe and complex international situation and the arduous tasks…

Tungsten components manufacture use Electron Beam Melting (abbreviation EBM) is an additive manufacturing method. Electrons accelerated under vacuum selectively melt metal powder…

The ratio?of coated cemented carbide tools in metal processing industry is increasing steadily. In recent 10 years, its quality and?performance?have been significantly…

Pure tungsten bar is made of 99.95% tungsten?power and its forging and annealing process?is shown by test. The bar?has physical properties e.g.…

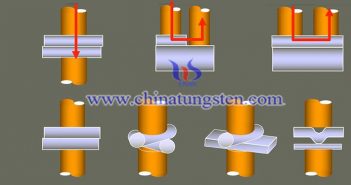

There are many factors, which can influence the welding effort of resistance welding, which is applied tungsten copper as electrodes, such as…

There are four types of resistance welding, which can use tungsten copper bonded copper electrode as welding tip, spot welding, seam welding,…

Tungsten copper is a material with high electricity conductivity, when using for resistance welding, the material is bonded with copper hand. This…

Compared with commercial graphite anode materials for lithium-ion batteries, nano-transition metal oxide anodes have better lithium storage properties and higher theoretical specific…

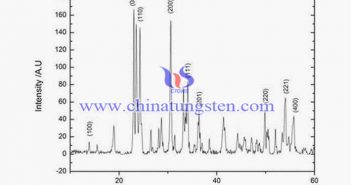

Network data shows that tungsten trioxide with a particle size in the range of 100nm-1000nm is called submicron yellow tungsten oxide. According…